PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

AZ stands for aluminum-zinc alloy, which is the material of the steel coating. AZ50 refers to the total weight of both sides of the aluminum-zinc alloy coating in the three-point test in ASTM a972 standard is 0.50 ounces/square foot, which is equivalent to 150 grams/square meter. It is a popular choice for roofing because it is very durable and can be painted in other colors.

AZ55 aluminum zinc plated steel coil is coated with 55% aluminum zinc alloy by hot dip plating process. It has excellent corrosion resistance and can be used in various applications, such as the automotive industry, shipbuilding industry, construction industry, etc. In addition to being an excellent outdoor material, AZ55 aluminized zinc steel coil also has many other advantages. For example, it can be used for electrical equipment manufacturing or decoration, such as fences. In addition to these uses, this steel can also be used in various industrial applications because of its good mechanical properties and corrosion resistance.

The thickness of AZ150 coating is 18 microns on one side and 36 microns on both sides. The coating alloy of the steel consists of 55% aluminium, 43.4 zinc and 1.6 silica. This coating of steel acts as a passive barrier to general corrosion. Once the sheet is exposed to electrolyte or moisture, another coating may form a galvanic cell. This exposure results in spillage of zinc ions and corrosion protection of the exposed steel. It also helps protect steel from trimmed edges and scratches.

Color Coated Galvalume Steel Sheet PPGL

The varieties that can be produced are: ordinary building materials board, purification board, cold storage board, solar panel, door and window profile, household appliance board, writing board, printing board, reticulated suede color coating, embossed printing, aluminum magnesium manganese color coating board, high weather resistance, silicon modification, self-cleaning board, heat reflection board, antibacterial board, acid and alkali resistant color coating board, etc., which can meet customer requirements of different industries and provide technical support and solutions.

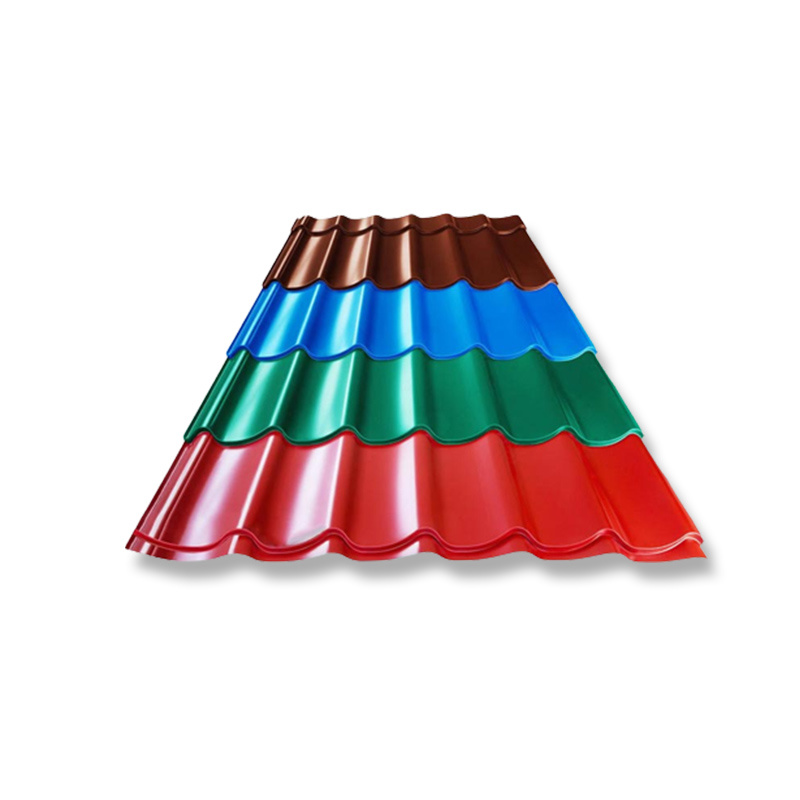

Corrugated color roof is a lightweight, strong, anti-corrosion building material. It is made of color-coated steel plate and designed in different styles, such as wavy, trapezoidal rib, tile, etc. In addition, our corrugated steel roof panels are available in many colors and sizes. Not only that, we also provide customized solutions to better meet your needs. Our color coated roof panels are suitable for many applications, such as garages, industrial workshops, agricultural buildings, barns, garden sheds, etc.

Color Coated Galvanized Roof Sheet PPGI

PPGI roof panels are beautiful and durable to meet your agricultural, residential and commercial needs. PPGI roof panels are available in a variety of different designs and sizes. Available thickness is 0.2 to 0.8mm, width is 600 to 1,250mm. In addition, colors and patterns are customizable.

Color Coated Galvalume Roof Sheet PPGL

PPGL roof panels are an excellent building material. Its weight is only 1/30 of the traditional concrete roof, which is easy to install and greatly shortens the construction period. It also maintains the strength and durability of the steel, allowing it to last more than 25 years under normal conditions. In addition, it is beautiful and generous, with various colors, patterns and patterns, which can meet different architectural styles. More importantly, PPGL steel has excellent heat resistance, which makes it an ideal roofing material even in hot climates. Whether it is home or investment, PPGL roof panels will be a good choice.

Prepainted Galvanized Steel Sheet

When steel components are used to make more complex finished products, they can be galvanized before the product is assembled. This is called pre-galvanizing, or "pre-galvanizing". It may also be referred to as "in-line", "continuous" or "rolled" galvanizing. Essentially, steel components (such as sheets or wires) are galvanized using an automated process before they are cut to size.