Galvanized Angle Steel

Classification :

PRODUCT DETAILS

Product Description

Galvanized angle steel is divided into hot-dip galvanized angle steel and cold galvanized angle steel. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. The cold galvanized coating mainly ensures the full contact between zinc powder and steel through electrochemical principle, and generates electrode potential difference for anti-corrosion. Hot dip galvanized angle steel is also called hot dip galvanized angle steel or hot dip galvanized angle steel. It is to immerse the angle steel after derusting in molten zinc melted at about 500 ℃ to attach a zinc layer to the surface of the angle steel, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs. The cold galvanizing process is used to protect the metal from corrosion. For this purpose, a coating of zinc filler is used. It is applied to the protected surface by any coating method and dried to form a zinc filler coating with a content of zinc in the dried coating (up to 95%). Suitable for repair work (I. e., during repair work, only where the protected steel surface is damaged, the surface can be recoated as long as it is repaired). The cold galvanizing process is used for corrosion protection of various steel products and structures.

Product Parameters

|

Material |

A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540 |

|

Scope of production |

H100*100-H400*400H150*75 -H900*300 |

|

Thickness |

1-30mm |

|

Width |

15-400mm |

|

Length |

6m, 9m, 12mor according to customer requirements |

|

Technology |

Hot rolled, welded |

|

Standard |

ASTM,AISI,JIS,GB, DIN,EN |

|

Surface |

Galvanized, painted;or according to your requirements |

|

supply capacity |

2000tons/Day |

|

Business Type |

Manufacturer |

|

Certificate |

ISO, SGS,BV |

|

Application |

Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

|

loading port |

Any port in China |

|

Packaging |

Standard export packing or as your request |

|

Payment Method |

Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

|

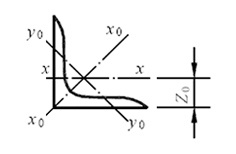

型号

|

|

单角钢 |

|

双角钢 |

|||||||||||||

|

圆角 |

重心矩 |

截面积 |

质量 |

惯性矩 |

截面模量 |

回转半径 |

iy, 当 a 为下列数值 |

||||||||||

|

R |

Z0 |

A |

Ix |

Wxmax |

Wxmin |

ix |

ix0 |

iy0 |

6mm |

8mm |

10mm |

12mm |

14mm |

||||

|

(mm) |

(cm2) |

(kg/m) |

(cm4) |

(cm3) |

(cm) |

(cm) |

|||||||||||

|

L90×

|

6 |

10 |

24.4 |

10.64 |

8.35 |

82.77 |

33.99 |

12.61 |

2.79 |

3.51 |

1.8 |

3.91 |

3.98 |

4.05 |

4.12 |

4.2 |

|

|

7 |

24.8 |

12.3 |

9.66 |

94.83 |

38.28 |

14.54 |

2.78 |

3.5 |

1.78 |

3.93 |

4 |

4.07 |

4.14 |

4.22 |

|||

|

8 |

25.2 |

13.94 |

10.95 |

106.5 |

42.3 |

16.42 |

2.76 |

3.48 |

1.78 |

3.95 |

4.02 |

4.09 |

4.17 |

4.24 |

|||

|

10 |

25.9 |

17.17 |

13.48 |

128.6 |

49.57 |

20.07 |

2.74 |

3.45 |

1.76 |

3.98 |

4.06 |

4.13 |

4.21 |

4.28 |

|||

|

12 |

26.7 |

20.31 |

15.94 |

149.2 |

55.93 |

23.57 |

2.71 |

3.41 |

1.75 |

4.02 |

4.09 |

4.17 |

4.25 |

4.32 |

|||

|

L100× |

6 |

12 |

26.7 |

11.93 |

9.37 |

115 |

43.04 |

15.68 |

3.1 |

3.91 |

2 |

4.3 |

4.37 |

4.44 |

4.51 |

4.58 |

|

|

7 |

27.1 |

13.8 |

10.83 |

131 |

48.57 |

18.1 |

3.09 |

3.89 |

1.99 |

4.32 |

4.39 |

4.46 |

4.53 |

4.61 |

|||

|

8 |

27.6 |

15.64 |

12.28 |

148.2 |

53.78 |

20.47 |

3.08 |

3.88 |

1.98 |

4.34 |

4.41 |

4.48 |

4.55 |

4.63 |

|||

|

10 |

28.4 |

19.26 |

15.12 |

179.5 |

63.29 |

25.06 |

3.05 |

3.84 |

1.96 |

4.38 |

4.45 |

4.52 |

4.6 |

4.67 |

|||

|

12 |

29.1 |

22.8 |

17.9 |

208.9 |

71.72 |

29.47 |

3.03 |

3.81 |

1.95 |

4.41 |

4.49 |

4.56 |

4.64 |

4.71 |

|||

|

14 |

29.9 |

26.26 |

20.61 |

236.5 |

79.19 |

33.73 |

3 |

3.77 |

1.94 |

4.45 |

4.53 |

4.6 |

4.68 |

4.75 |

|||

|

16 |

30.6 |

29.63 |

23.26 |

262.5 |

85.81 |

37.82 |

2.98 |

3.74 |

1.93 |

4.49 |

4.56 |

4.64 |

4.72 |

4.8 |

|||

|

L110× |

7 |

12 |

29.6 |

15.2 |

11.93 |

177.2 |

59.78 |

22.05 |

3.41 |

4.3 |

2.2 |

4.72 |

4.79 |

4.86 |

4.94 |

5.01 |

|

|

8 |

30.1 |

17.24 |

13.53 |

199.5 |

66.36 |

24.95 |

3.4 |

4.28 |

2.19 |

4.74 |

4.81 |

4.88 |

4.96 |

5.03 |

|||

|

10 |

30.9 |

21.26 |

16.69 |

242.2 |

78.48 |

30.6 |

3.38 |

4.25 |

2.17 |

4.78 |

4.85 |

4.92 |

5 |

5.07 |

|||

|

12 |

31.6 |

25.2 |

19.78 |

282.6 |

89.34 |

36.05 |

3.35 |

4.22 |

2.15 |

4.82 |

4.89 |

4.96 |

5.04 |

5.11 |

|||

|

14 |

32.4 |

29.06 |

22.81 |

320.7 |

99.07 |

41.31 |

3.32 |

4.18 |

2.14 |

4.85 |

4.93 |

5 |

5.08 |

5.15 |

|||

|

L125× |

8 |

14 |

33.7 |

19.75 |

15.5 |

297 |

88.2 |

32.52 |

3.88 |

4.88 |

2.5 |

5.34 |

5.41 |

5.48 |

5.55 |

5.62 |

|

|

10 |

34.5 |

24.37 |

19.13 |

361.7 |

104.8 |

39.97 |

3.85 |

4.85 |

2.48 |

5.38 |

5.45 |

5.52 |

5.59 |

5.66 |

|||

|

12 |

35.3 |

28.91 |

22.7 |

423.2 |

119.9 |

47.17 |

3.83 |

4.82 |

2.46 |

5.41 |

5.48 |

5.56 |

5.63 |

5.7 |

|||

|

14 |

36.1 |

33.37 |

26.19 |

481.7 |

133.6 |

54.16 |

3.8 |

4.78 |

2.45 |

5.45 |

5.52 |

5.59 |

5.67 |

5.74 |

|||

|

L140×

|

10 |

14 |

38.2 |

27.37 |

21.49 |

514.7 |

134.6 |

50.58 |

4.34 |

5.46 |

2.78 |

5.98 |

6.05 |

6.12 |

6.2 |

6.27 |

|

|

12 |

39 |

32.51 |

25.52 |

603.7 |

154.6 |

59.8 |

4.31 |

5.43 |

2.77 |

6.02 |

6.09 |

6.16 |

6.23 |

6.31 |

|||

|

14 |

39.8 |

37.57 |

29.49 |

688.8 |

173 |

68.75 |

4.28 |

5.4 |

2.75 |

6.06 |

6.13 |

6.2 |

6.27 |

6.34 |

|||

|

16 |

40.6 |

42.54 |

33.39 |

770.2 |

189.9 |

77.46 |

4.26 |

5.36 |

2.74 |

6.09 |

6.16 |

6.23 |

6.31 |

6.38 |

|||

|

L160×

|

10 |

16 |

43.1 |

31.5 |

24.73 |

779.5 |

180.8 |

66.7 |

4.97 |

6.27 |

3.2 |

6.78 |

6.85 |

6.92 |

6.99 |

7.06 |

|

|

12 |

43.9 |

37.44 |

29.39 |

916.6 |

208.6 |

78.98 |

4.95 |

6.24 |

3.18 |

6.82 |

6.89 |

6.96 |

7.03 |

7.1 |

|||

|

14 |

44.7 |

43.3 |

33.99 |

1048 |

234.4 |

90.95 |

4.92 |

6.2 |

3.16 |

6.86 |

6.93 |

7 |

7.07 |

7.14 |

|||

|

16 |

45.5 |

49.07 |

38.52 |

1175 |

258.3 |

102.6 |

4.89 |

6.17 |

3.14 |

6.89 |

6.96 |

7.03 |

7.1 |

7.18 |

|||

|

|

12 |

16 |

48.9 |

42.24 |

33.16 |

1321 |

270 |

100.8 |

5.59 |

7.05 |

3.58 |

7.63 |

7.7 |

7.77 |

7.84 |

7.91 |

|

|

14 |

49.7 |

48.9 |

38.38 |

1514 |

304.6 |

116.3 |

5.57 |

7.02 |

3.57 |

7.67 |

7.74 |

7.81 |

7.88 |

7.95 |

|||

|

16 |

50.5 |

55.47 |

43.54 |

1701 |

336.9 |

131.4 |

5.54 |

6.98 |

3.55 |

7.7 |

7.77 |

7.84 |

7.91 |

7.98 |

|||

|

18 |

51.3 |

61.95 |

48.63 |

1881 |

367.1 |

146.1 |

5.51 |

6.94 |

3.53 |

7.73 |

7.8 |

7.87 |

7.95 |

8.02 |

|||

|

L200× |

14 |

18 |

54.6 |

54.64 |

42.89 |

2104 |

385.1 |

144.7 |

6.2 |

7.82 |

3.98 |

8.47 |

8.54 |

8.61 |

8.67 |

8.75 |

|

|

16 |

55.4 |

62.01 |

48.68 |

2366 |

427 |

163.7 |

6.18 |

7.79 |

3.96 |

8.5 |

8.57 |

8.64 |

8.71 |

8.78 |

|||

|

18 |

56.2 |

69.3 |

54.4 |

2621 |

466.5 |

182.2 |

6.15 |

7.75 |

3.94 |

8.53 |

8.6 |

8.67 |

8.75 |

8.82 |

|||

|

20 |

56.9 |

76.5 |

60.06 |

2867 |

503.6 |

200.4 |

6.12 |

7.72 |

3.93 |

8.57 |

8.64 |

8.71 |

8.78 |

8.85 |

|||

|

24 |

58.4 |

90.66 |

71.17 |

3338 |

571.5 |

235.8 |

6.07 |

7.64 |

3.9 |

8.63 |

8.71 |

8.78 |

8.85 |

8.92 |

|||

Packing and shipping

It possesses two wide and heavy steel plate production lines including one 4100mm line and one 4200mm line of high specialization, with international first class technological equipment and the comprehensive capacity of annually producing over 5 million tons of molten steel and 3 million tons of steel plate. The total assets are 13.2 billion yuan. The number of employees amounts to more than 10,000. The company covers an area of 7.35 m2. The total area of industrial building at plant site is 4.4 million m2. The steel plate heat treatment technology, extra heavy steel plate production technology and ESR steel production technology are all in the leading position of the same industry.

CUSTOMER VISIT

HONOR CERTIFICATE

PARTNER

FACTORY WORKSHOP

Factory Workshop

Factory Workshop

Factory Workshop

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE